AWS CWI Part C - Session 1 (Clause 1) - Click for PPT

AWS CWI Part C

Welding of Pipelines and Related Facilities (API Standard 1104)

-

AWS CWI Part C is an open book examination with the standard given to the candidates.

-

The candidates are required to identify the location of the answer by giving the clause and sub-clause number.

-

AWS CWI Part C would be covered in four modules comprising thirteen sessions.

-

The Part C presentation would include the interactions comprising of questions to be answered in the presentation.

-

At the end of each session, an assessment would be attempted to check the candidate grasping power.

-

In Session 1 - SCOPE would be covered. Let’s start with the session 1

1. Session (Clause) 1 is Scope

The scope of the API standard 1104 is that

- API 1104 provides a list of eight permitted welding processes. They are listed SMAW, SAW, GTAW, GMAW, FCAW, PAW, OAW, and FW.

- API 1104 also states that these processes may be applied using manual, semiautomatic, mechanized, or automatic welding techniques or a combination of these techniques.

- API 1104 covers procedures for various NDT methods and the acceptance standards to be applied to production welds. The NDT methods to be covered are RT, MT, PT, UT, and VT

1.1 Document Types

The type documents referred during the training are

- CODE: A Code is a body of laws arranged systematically for easy reference and use. example AWS D1.1

- STANDARD: A Standard is established for use as a rule or basis of comparison in measuring quality, quantity, content, relative value. example API Standard 1104

- SPECIFICATION: A specification is a detailed description of the parts of a whole; a statement or enumeration of particulars, as to actual or required size, quality, performance, terms, etc example AWS A5.1 Filler Metal Specification

- A RECOMMENDED PRACTICE is a description of generally accepted industrial methods and techniques. example SNT-TC-1 A,

1.2 Footnotes

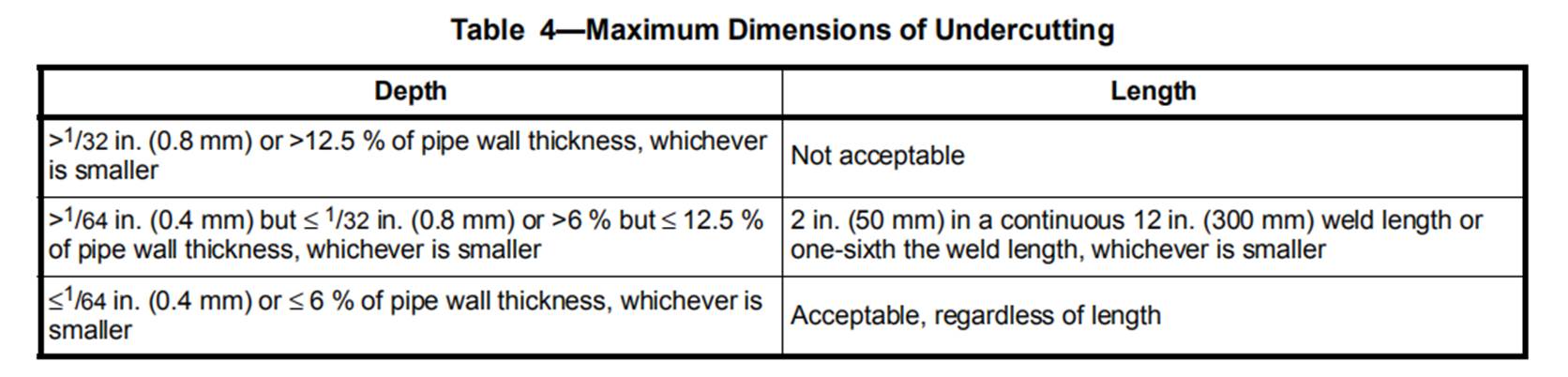

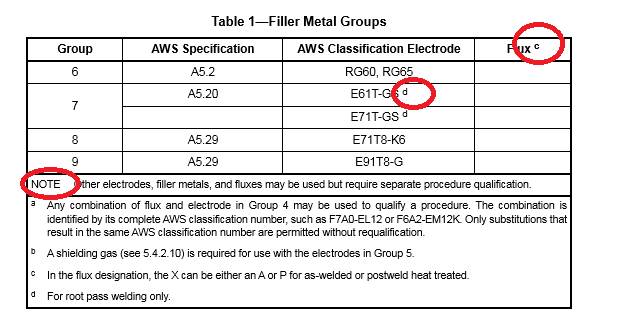

Numbers of questions in API 1104 come from FOOTNOTES of a Table, which are

- Global or general footnote - these appear in the title of a figure, list, or table and they influence all provisions from that figure, list, or table. Sometimes general footnotes are located in the footer of a table or figure and are labeled as “NOTE(S)

- Regional footnotes - these appear in the column header or at the end of a row title in a table or at the top of a subsection and influence only that column or row of the table or that specific subsection of text.

- Local or specific footnotes - these apply only to the specific item being footnoted.

The footnotes have been explained with the help of the table with red encircled figures. The detailed meaning of suffix letters of a, b, c and d have been explained in the footnotes below.

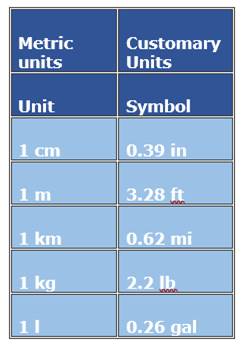

1.3 Measurement System: The measurement systems in practice are

- US Customary also known as USC and is in “inches” i.e. “in.”

- SI –System Internationale is in “mm” and is in the (brackets)

- API 1104 refers to both the Measurement systems

1.4 Permitted Welding Process

Eight Permitted Welding Processes as per the standard are tabulated below with four techniques of manual, semi-automatic, mechanized and automatic.

The applicable process has been shown in cross for the applicable process and technique.

1.5 Five Permitted NDT Techniques as per the standard are tabulated

- Radiographic testing (RT).

- Magnetic particle testing (MT).

- Liquid Penetrant testing (PT).

- Ultrasonic testing (UT).

- Visual testing (VT).

1.6 Welding Techniques

Welding Techniques for different methods for automatic Welding, mechanized welding and semi-automatic welding are given on the slide

1.6.1 Automatic Welding has

- With equipment

- Without manual manipulation

- Without guiding or tracking

- Without a manual skill

1.6.2 Mechanized Welding has

- Process where parameters and torch guidance are controlled mechanically or electronically but may be manually varied during welding to maintain specified welding conditions

1.6.3 Semi-Automatic welding has

- Only Filler metal feed is done by Equipment

Let us view the PPT by pressing the icon on the right bottom corner.